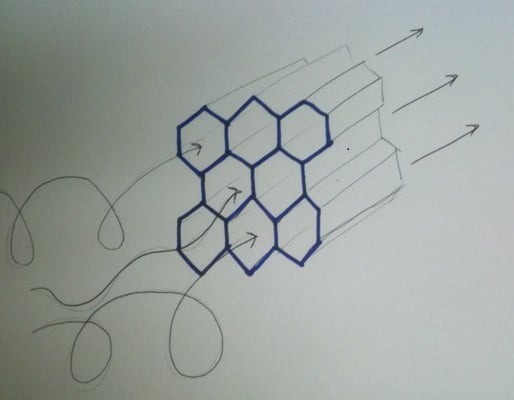

Aluminium Honeycomb for Air Conditioning Wind Tunnels Diffusing Shielding Sacrificial beds. For this purpose a honeycomb 15 is placed at the entrance of the tunnel Figure 12.

Understanding Wind Tunnel Design 3 Must Components F1

Corex Honeycomb offers a material that does not significantly alter the weight of applied.

. Given their ubiquitous nature and utility a wind-tunnel design project is a. From now on we will be a little. The flow stabilizer is the first section of the wind tunnel and is responsible for channeling clean laminar and turbulence-free air into the remainder of the tunnel.

There are five main parts to this design. Aluminium honeycomb is suitable for use in a range of specialised applications including air conditioning wind tunnels diffusing electromagnetic shielding flow straightening and sacrificial beds. Large yaw angles will cause.

The Science Buddies wind tunnel uses zip ties to attach the honeycomb mesh to a series of staples on the outside rim of the Contraction. Wind Tunnel Design Fabrication Service Since 1947 See Our Products 70 Years of Innovative Engineering For Proven Products Indoor Skydiving Wind Tunnels Blow Down Wind Tunnels Flow Viz Tunnel Model Positioning System Traverse Systems Water Tunnels Channels Product Types See All Products Recent Projects See All Case Studies 01 Honeywell Aerospace Aerolab. Scheiman J Considerations for the installation of honeycomb and screens to reduce wind-tunnel turbulence NASA Technical Memorandum 81868 NASA Washington 1981.

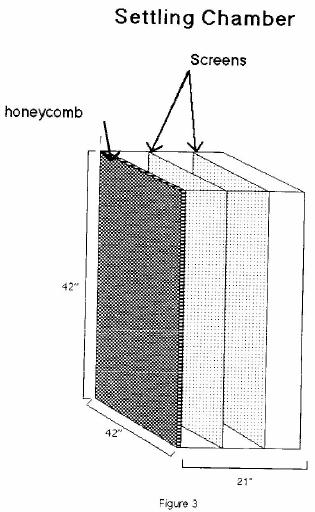

The Royal Aeronautical Society. Wind tunnel Design Settling chamber. Wind Tunnel Design 10 Wind tunnels generate uniform air flows with low turbulence intensity for thermal and hydraulic testing.

These devices have been around for more than a century and are used in many industries including aerospace automotive and defense. It consists of one honeycomb one mesh and a settling distance. Aluminum Honeycomb Flow Straightener.

Should have one honeycomb and ve screens. This tunnel can be built for less than 100 and uses a computer fan motor to move air past small models. We are discussing today what is known at the honeycomb.

Wind tunnel Design Settling chamber. Role of Honeycomb in Improving Subsonic Wind Tunnel Flow Quality. Low Turbulence Wind Tunnel Design and Wind Turbine Wake Characterization Andrew Welsh University of Wisconsin-Milwaukee Follow this and additional works athttpsdcuwmeduetd Part of theMechanical Engineering Commons and theOil Gas and Energy Commons This Thesis is brought to you for free and open access by UWM Digital Commons.

This price estimate is the result of shopping around for the least-expensive products available that would still work properly in the wind tunnel. Completely customized to your specific needs. Depends how big is the inlet of your wind tunnel.

Dear Fellow Basement Scientists Here we are placing the last finishing touches on the entrance to the wind tunnel. This is pretty exciting. The wind-tunnel design In 1995 it was decided to build a new low-speed wind-tunnel as a complement to the larger MTL wind-tunnel already operating at the Department of Me-.

Wind Generators produce a circular jet of air at variable speeds. DESIGN CFD SIMULATION AND CONSTRUCTION. Honeycomb is the most efficient device for removing swirl and lateral velocity variations and to make the flow more parallel to the axial axis 2.

Some Basic Principles of Wind Tunnel Design. They also play a key role in electronics thermal management. Eagle specializes in electric motor drives and motion control.

September 14 2011 by Ben Washington. Together we have decades of experience and a. For your reference the air moves from the left to right.

Numerical Study Based on Orthogonal Grid 353 tunnels has been evolved by Moonen et al. Wind tunnels generate uniform air flows with low turbulence intensity for thermal and hydraulic testing. Different option from which a honeycomb structure can be made.

Honeycomb design criteria To improve the relevance of output data it is necessary to design and create an optimal screen suited for the conditions of this wind tunnel. To reduce the amount of turbulence in the flow Scheiman and Brooks 1 found that using a honeycomb with a. Contraction Cone Nozzle Outlet.

Wind Tunnel Honeycomb. They also design and fabricate specialty mechanical systems such as automated rod cutters and conveyor systems. I would like to know the guideline for the honeycomb diameter - wind tunnel size ratio.

Little Smokey - Flow Visualization Wind Tunnel. The Science Buddies wind tunnel design cost about 275. First on the far left is the bell mouth which is like a nozzle.

If it is small you can make it by yourself. Journal Royal Aeronautical Society 73 443 1979. Second is the tunnel which is straight and holds our specimens.

Wind tunnel Design Pressure losses 1 Pressure loss in constant cross section. It will be costly if you fabricate it outside. 3 to evaluate the CFD function in wind tunnel measuring and design.

So far I only got to know that the diameter - length of this honeycomb is approx18. Darchem has a proven track record of design test manufacture and installation of metallic honeycomb products for the nuclear aerospace automotive and rail markets for over 40 years. Plywood skilled carpentry required.

The honeycomb affects the flow uniformity and the screens and Wind-tunnel design should be tailored to meet the specific subsequent settling duct length dictate the turbulence inten- research goals and is subject to budget and facility space lim- sity in the test section. It was also decided that the wind-tunnel should be equipped with a heat exchanger. The honeycomb flow field is even and uniform to meet the characteristics of different flow field that has been used world wise in wind tunnel water flow design and by companies for engine testing aircraft testing and automotive testing etc.

Here is a wind tunnel design that was developed at NASA Glenn during the Centennial of Flight Celebration in 2003. Report this post Antonio Navarro-Manso. This is the same con-.

We are a Proven Leader. Honeycomb typical cell size range. Answer 1 of 3.

According to Metha Bradshaw 1979 as far as the design method is concerned the honeycomb length the cell hydraulic and the porosity are design key factors. Complete plans for the tunnel can be downloaded for free from the web page. It starts larger and funnels the air into the tunnel of our wind tunnel.

Working with customers to design specialised honeycomb products typical honeycomb specifications are. The Wind Tunnel Company is located in Baltimore Maryland USA and is a division of Eagle Engineering Corporation. Wind tunnels offer an effective tool to rapidly obtain data associated with flow over scaled or full-scale models.

Screens To have effective reducing in turbulence the porosity must lie between 058 to 08 Different mesh qualities coarse medium f ine are efficient than single fine mesh 28. D and Bradshaw P Design Rules for Small Low-Speed Wind Tunnels Aero.

Wind Tunnel Honeycomb Basement Science

The Wind Tunnel Used To Alter Experimental Wind Conditions Sections Download Scientific Diagram

Numerical Wind Tunnel Model Mesh Download Scientific Diagram

Wind Tunnel Honeycomb Basement Science

Leading Edge Indoor Skydiving Technology Tunneltech

China Honeycomb Flow Straightener For Wind Tunnel Or Water Tunnel For Fluid Test China Honeycomb Flow Straightener Air Directionalization

Schematic Of A Hexagonal Honeycomb Section Download Scientific Diagram

0 comments

Post a Comment